Drone Inspections

VisioStack has joined with railway partners and the SBIR research program to develop innovative, drone-based solutions for inspecting track components. This opens new possibilities for conducting inspections in difficult or dangerous conditions, and for streamlining general inspections.

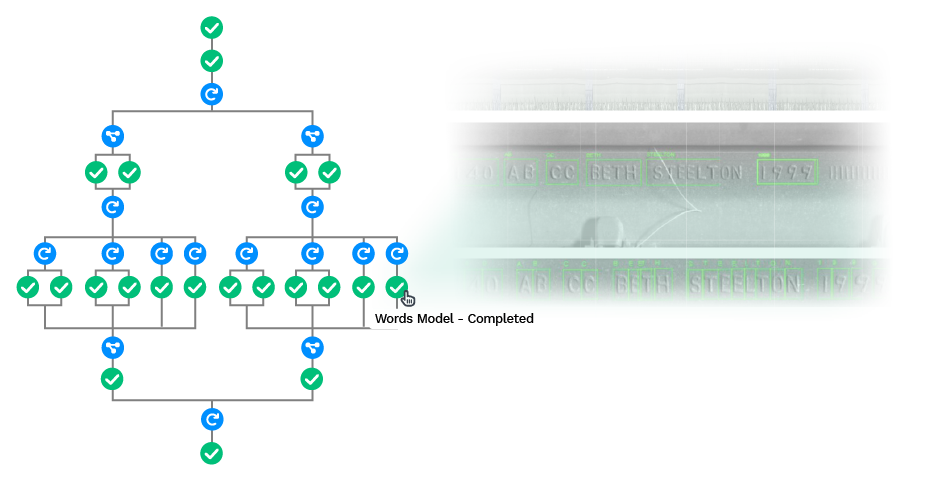

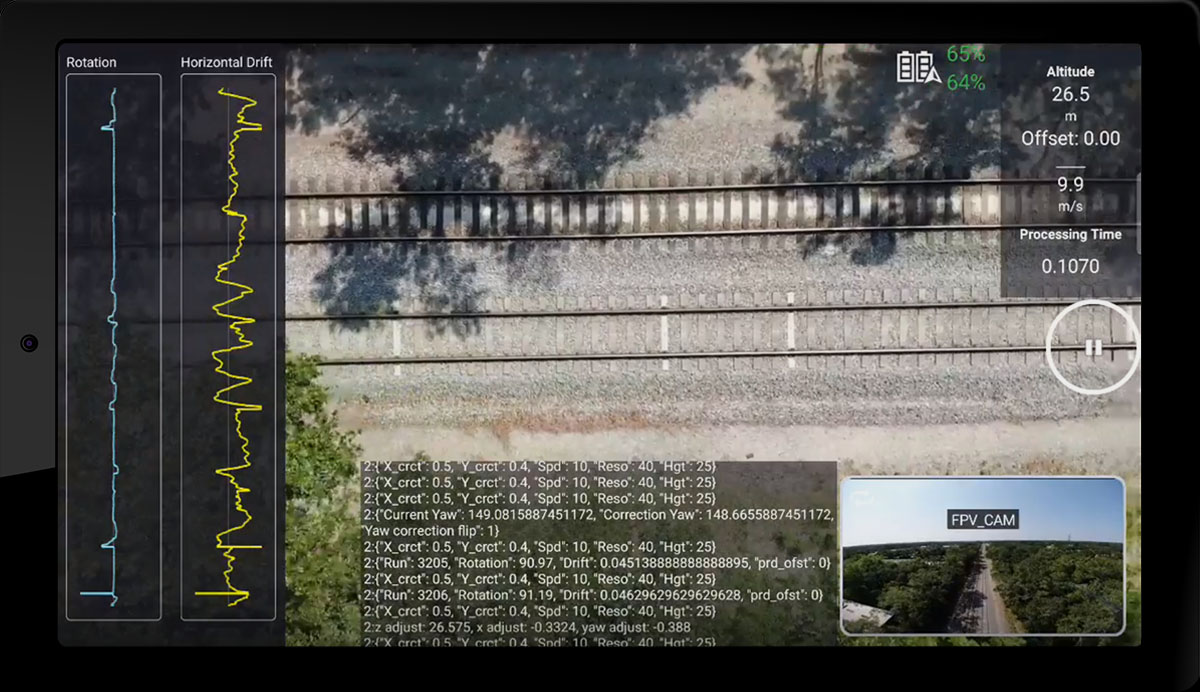

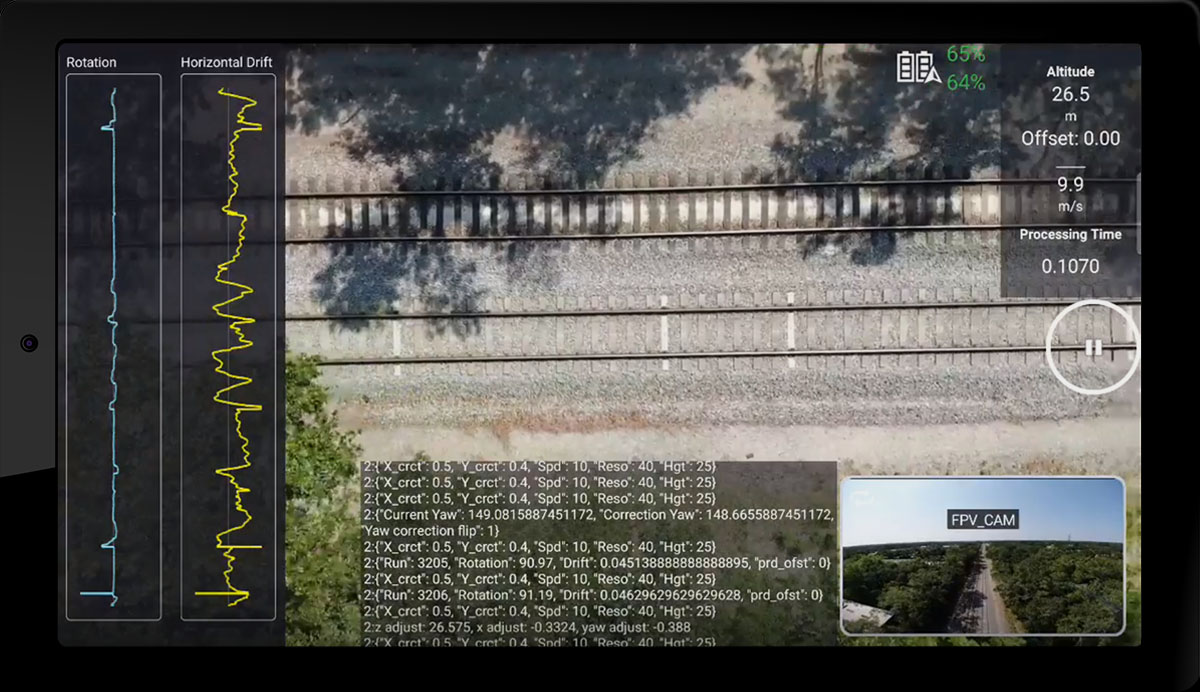

Autopilot & Track Scanning

A smart drone inspection requires the ability to follow a track and the ability to quickly process basic track geometry. VisioStack has completed projects on both of these fronts, creating software that can guide a drone along the length of a track while mapping ties, rails, and centerlines.

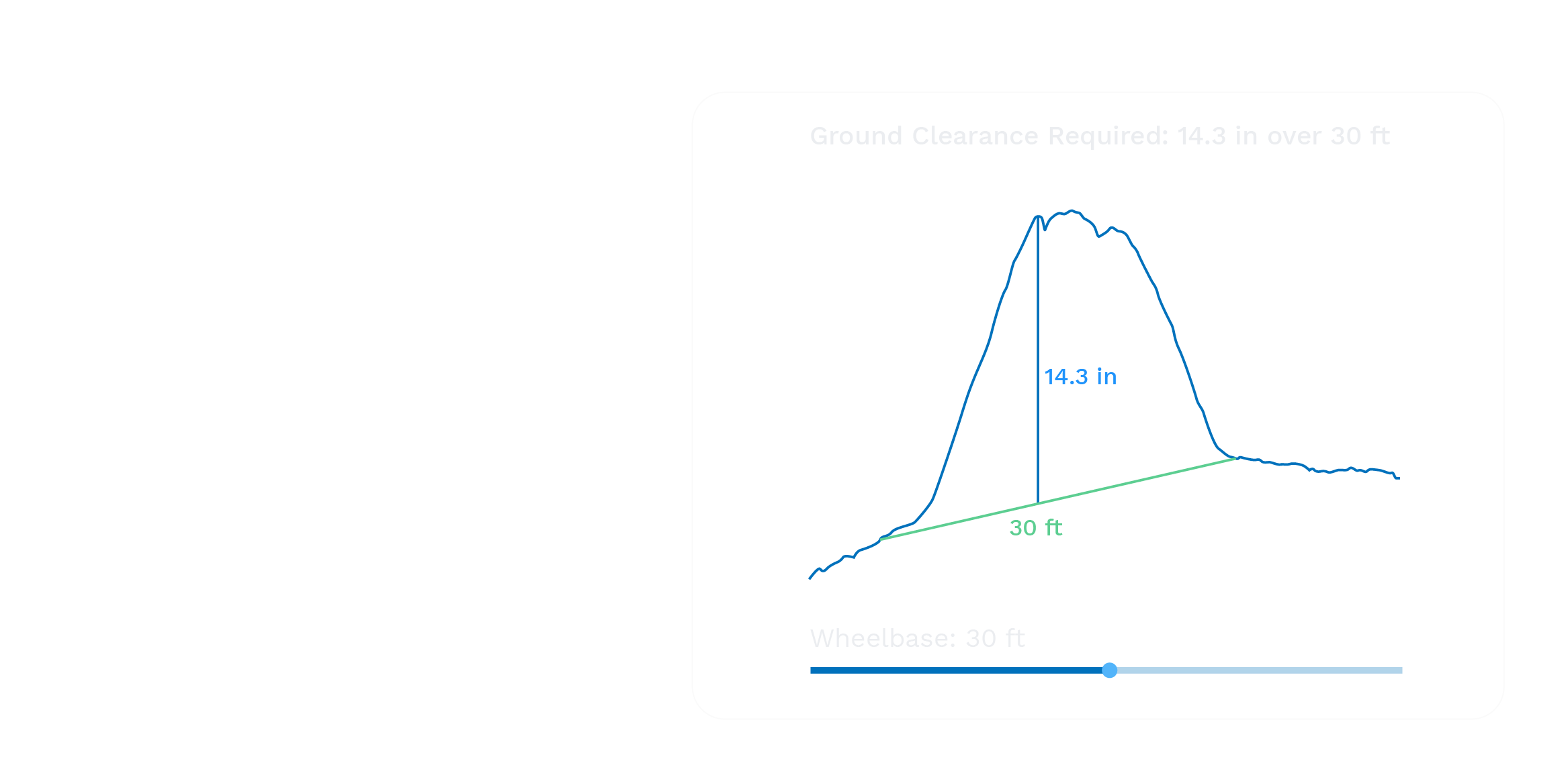

Crossing Measurement

There are thousands of safety-related incidents each year across the globe at railway crossings. When maintenance responsibilities are shared across multiple stakeholders—railways, municipalities, and regulatory bodies—crossing management requires focused accountability.

Many incidents at crossings involve vehicles with low clearances, or areas where lines of sight and visibility are limited. We aim to reduce incidents through innovative assessment of risk, by measuring and reporting on these geometries through drone scanning.

VisioStack's AXIS (Aerial Crossing Inspection System) inspection process uses off-the-shelf drone technology to improve risk assessment at crossings. Combined with a railway's existing crossing asset information, AXIS delivers automation including flight pre-planning, execution & collection, data transfer, and generation of reports.