Field Inspection

RailLinks® Field Inspection and Scheduling is designed to facilitate the everyday requirements of regulatory compliance and maintenance operations. The platform is built on the principle of flexible form creation, giving control to maintainers. It also adapts to any device form factor, enabling organizations with a Bring Your Own Device (BYOD) policy to easily adopt the technology.

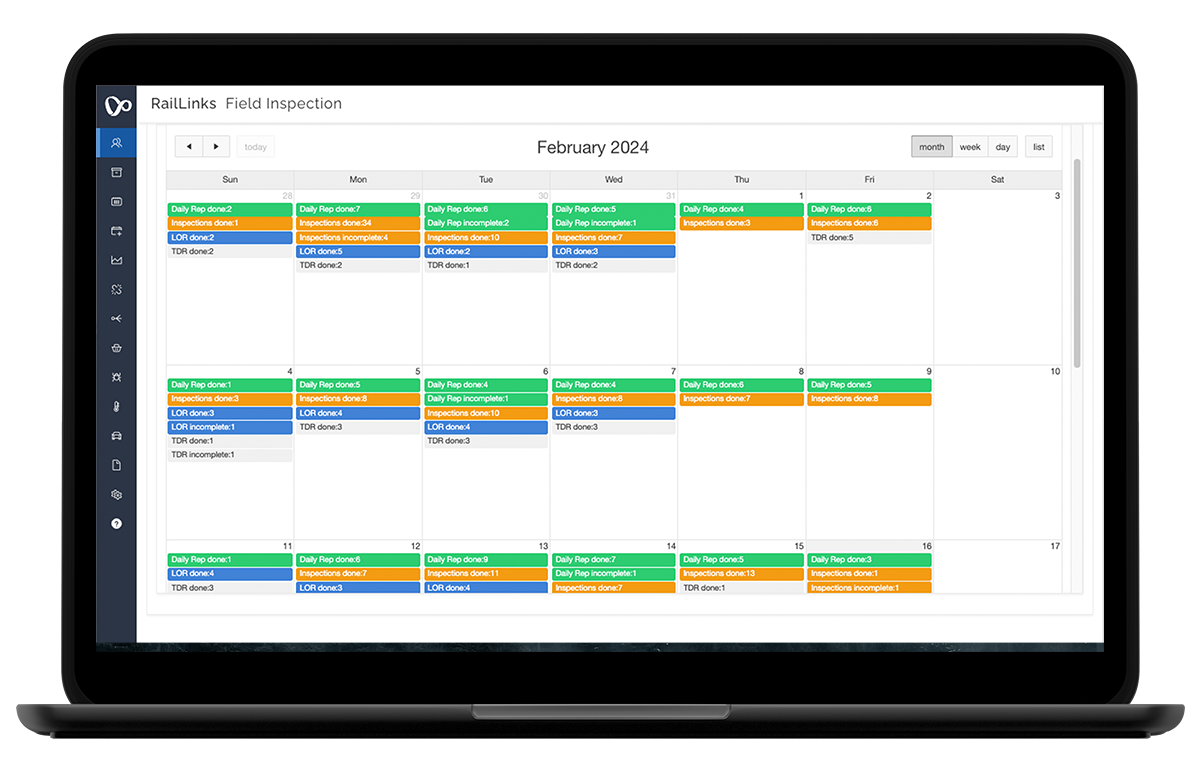

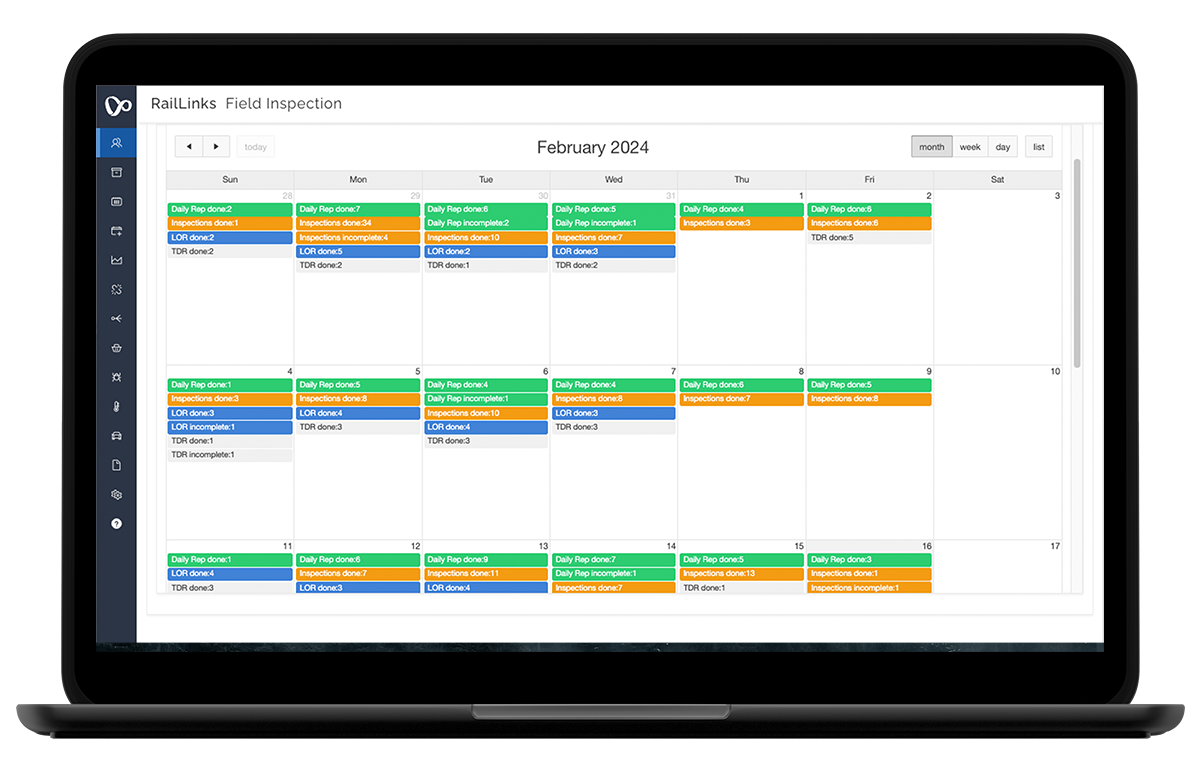

Scheduling & Reminders

A compliance standards repository contains the basic definitions, divided into subparts, describing how and when inspections should be carried out. This provides the baseline for inspectors on what tasks need to be completed, and with what frequency they need to be completed.

The platform allows several means of scheduling inspections. A scheduling dashboard allows an administrator to create and view an inspection schedule in advance. Inspections which haven't been scheduled in advance may still be recorded and added to the repository—both calendar and lists—as completed inspections. Completed or scheduled inspections can be exported to standard formats such as CSV or to external enterprise systems, when available.

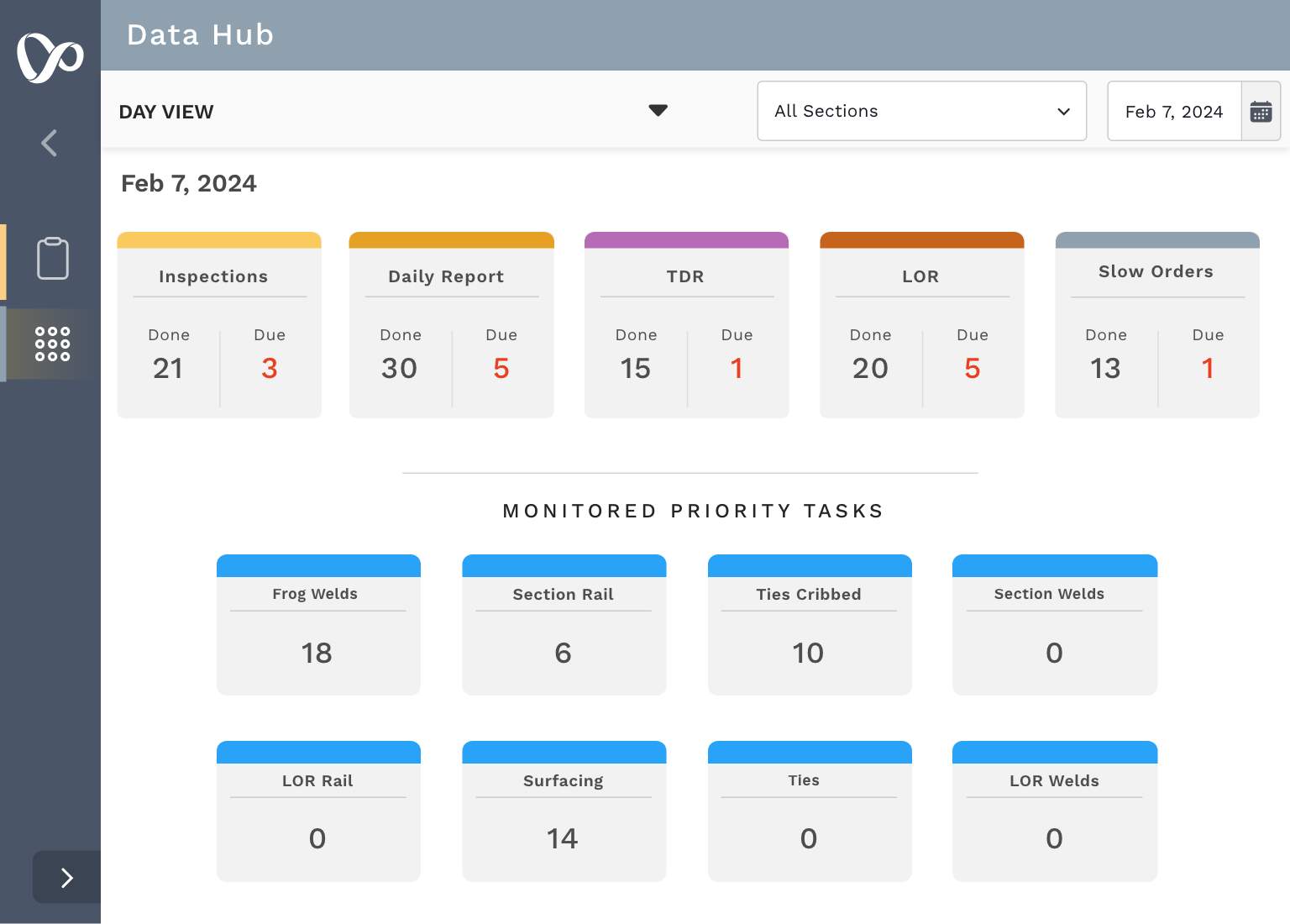

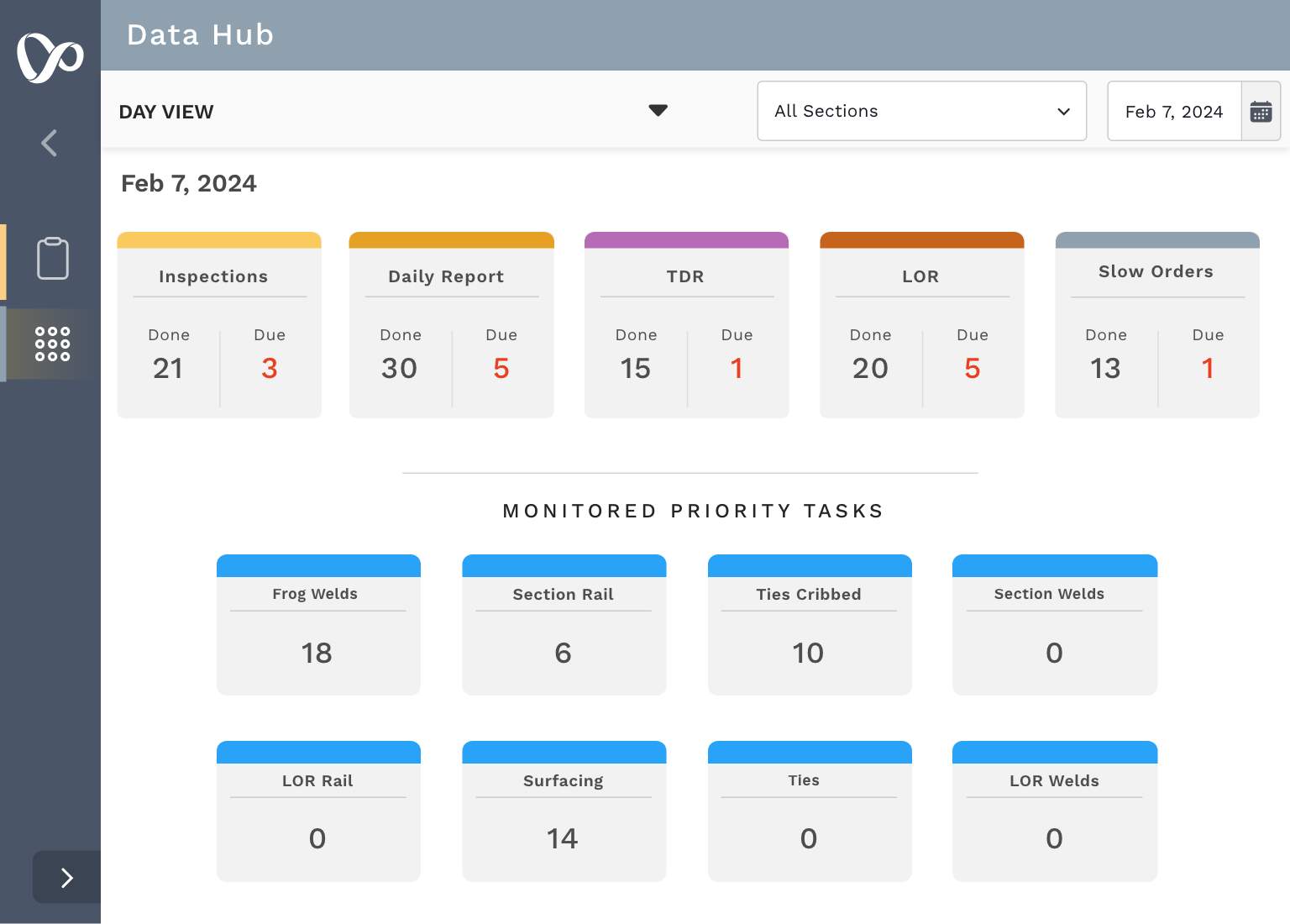

Prioritized Dashboards

Field Inspection uses prioritized dashboards which allow individual users to track recently completed, upcoming, and overdue inspections. It also integrates defects from automated vehicles.

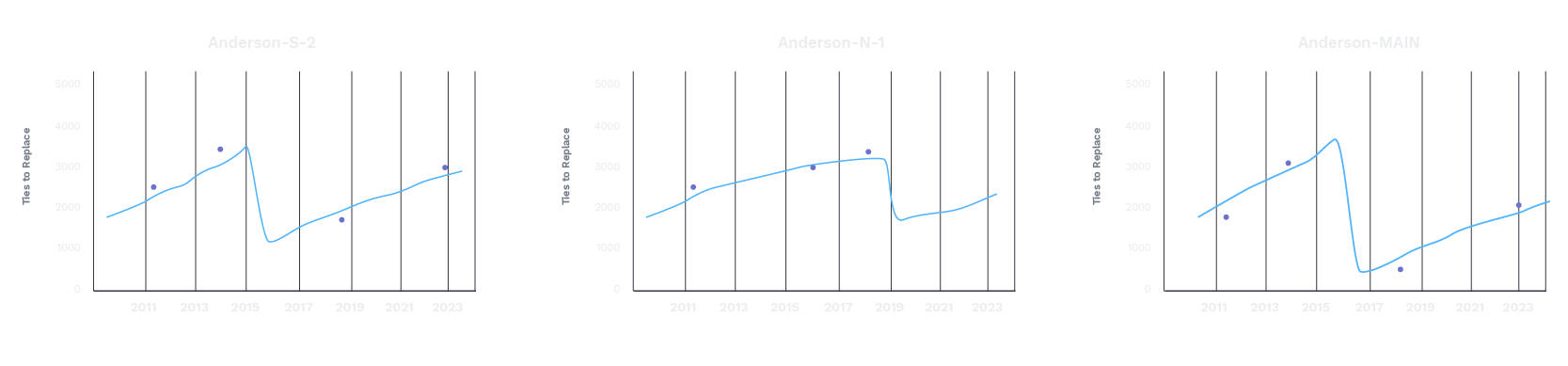

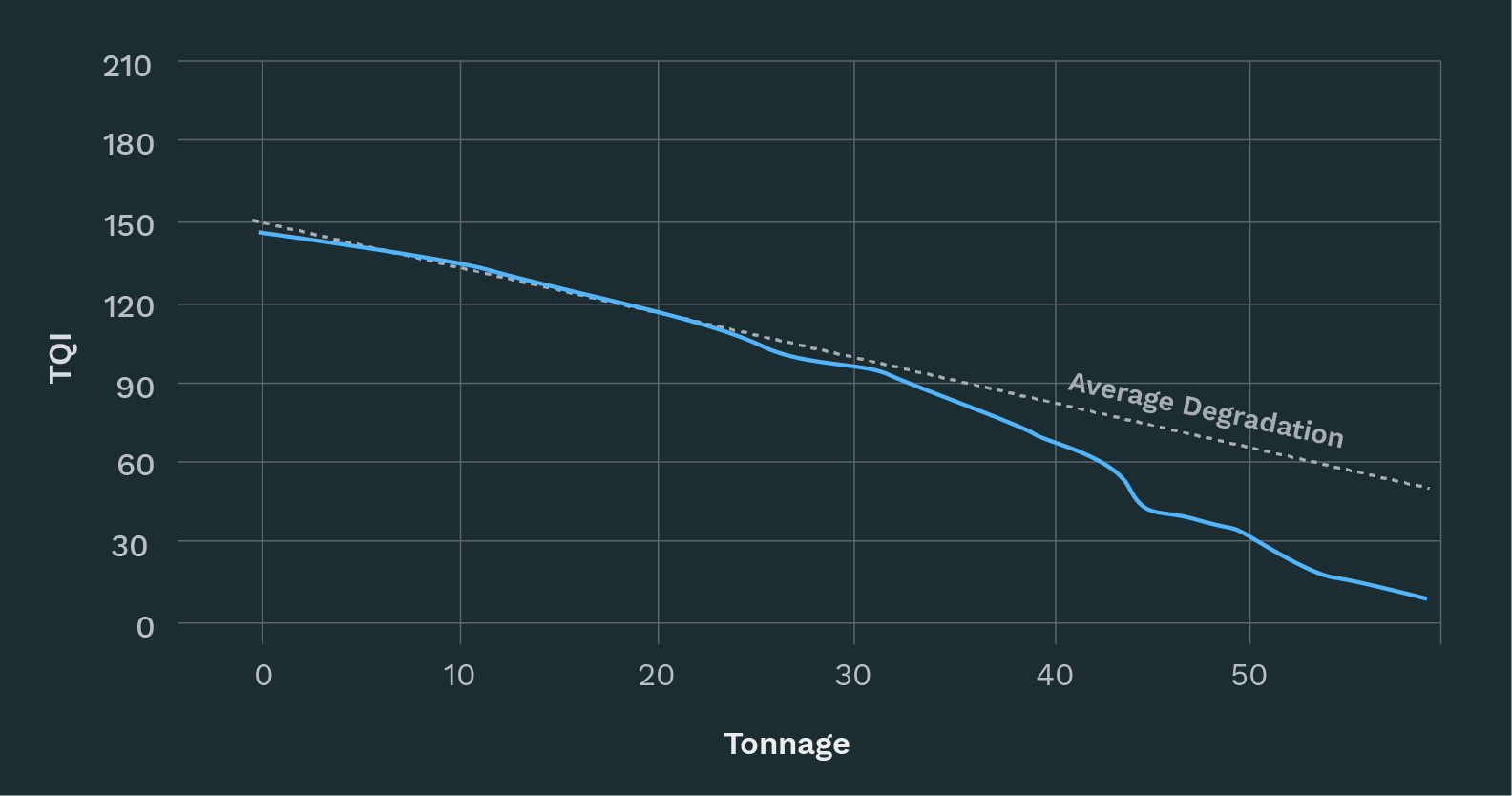

Record keeping for future planning

Our platform ensures maintainers have a repository of historical work, organized in a way that facilitates future planning. Common maintenance activities such as brushcutting, surfacing, tie replacement, rail replacement, welding, and grinding are tracked, along with materials and associated cost information.